Gear Hobbing

We have a wide range of gear hobbing capabilities – both conventional wet hobbing and dry hobbing.

The cutting speed of Mitsubishi GE25A dry hobbing machine is double compare to conventional machines.

We have a wide range of gear hobbing capabilities – both conventional wet hobbing and dry hobbing.

The cutting speed of Mitsubishi GE25A dry hobbing machine is double compare to conventional machines.

Spur and helical gears with different specifications can be produced by gear shaping. Our gear shaping machines can produce internal and external gears.

Gear grinding remains the most common process for hard finishing. There are many benefits including improved gear quality and the correction of heat treatment distortion. We have a wide range of gear grinding equipment for spur, helical and bevel gears.

Gear honing is probably the most efficient of all gear finishing processes.

The process uses an abrasive impregnated gear tool with the honing action providing an excellent surface – free from grinding burn. Gear honing prolongs the wear life and increases the load carrying capacity by improving the surface contact area.

The surface structure produced by honing means the gears produce less noise and have a longer use life.

| Description | Process | Quality | Pitch | Quality | Module |

|---|---|---|---|---|---|

| Spur and Helical Gear |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Worm |

|

|

|

||

|

|

|

|||

|

|

|

|||

| Worm Gear |

|

|

|

||

| Spiral Bevel Gear |

|

|

|

|

|

|

|

|

|

|

|

| Straight Bevel Gear |

|

||||

| Spline Shaft |

|

| Machine | Country | Maker | Type | Qty |

|---|---|---|---|---|

| Gear Hobbing | Japan | Kashifuji | KL-1000(CNC) | 1 |

| KN-150(CNC) | 5 | |||

| KA-400(CNC)/KB-400(CNC) | 6 | |||

| KA-220(CNC) | 6 | |||

| KA-80(CNC) | 2 | |||

| KE-250 | 1 | |||

| Mitsubishi (Chamfering) | GB63(CNC) | 1 | ||

| GC150(CNC) | 2 | |||

| GD30(CNC) | 1 | |||

| GE25A Dry Hobbing Machine | 2 | |||

| GE20A Dry Hobbing Machine | 8 | |||

| Hamai | 60SP | 2 | ||

| Seiwa | MPN-12 | 2 | ||

| Swiss | Pfauter Mikron | A15(CNC) | 1 | |

| Gleason-Pfauter | P60(CNC) | 1 | ||

| P90(CNC) | 3 | |||

| Germany | Pfauter | PF300 | 5 | |

| Master Gear Grinding Machine | Taiwan | Luren | LUG-3040 | 1 |

| Spline Grinder | Japan | Okamoto | SSG | 2 |

| Turning | Taiwan | Vturn | V-TURN20/26 | 6 |

| TAKISAWA | NEX-110 | 5 | ||

| Goodway | GA-2000 | 2 | ||

| Japan | Okuma | GENOS L3000-e | 2 | |

| Spline Rolling | Japan | Nachi | PFFM-915XTHNC | 2 |

| Gear Chamfering | Taiwan | I- CHIANG | 2 | |

| Broaching | Japan | Nachi | NBx 7.5-10 | 2 |

| Bore Grinding | Taiwan | ETECH | EGM-350 | 3 |

| OD Grinding | Taiwan | ETECH | EGA-3260 | 6 |

| Japan | Mitsubishi | PD 32 | 2 | |

| Taiwan | Goodway | GRA-2060 | 3 | |

| Gear Grinding Machine | Swiss | Reishauer | RZ820(CNC) | 1 |

| RZ301S(CNC) | 1 | |||

| RZ300E | 5 | |||

| RZ400 | 3 | |||

| RZ362(CNC) | 1 | |||

| RZ260 (Twist) | 2 | |||

| Japan | Mitsubishi | ZE24B | 1 | |

| Germany | Liebherr | LGG280 (Twist) | 10 | |

| KAPP | KX260 Twin (Twist) | 2 | ||

| Gear Shaper | Germany | Lorenz | SN4/SN5 | 2 |

| Liebherr | LS120 with Autoloader | 1 | ||

| Japan | Mitsubishi | SC25(CNC) | 3 | |

| SD15(CNC) | 2 | |||

| SD25(CNC) | 1 | |||

| ST40(CNC) Electronic Guide | 2 | |||

| SE25A(CNC) Electronic Guide | 1 | |||

| SE25FR(CNC) | 1 | |||

| Gear Shaver | Japan | Kanzaki | GSH-400C | 8 |

| GSK-400C-NC4 | 2 | |||

| USA | Red Ring | GCU | 2 | |

| Worm Grinding Machine | Germany | Klingelnberg | HSS-350 | 1 |

| Taiwan | Luren | LWT-2050 | 1 | |

| China | S7720A | 2 | ||

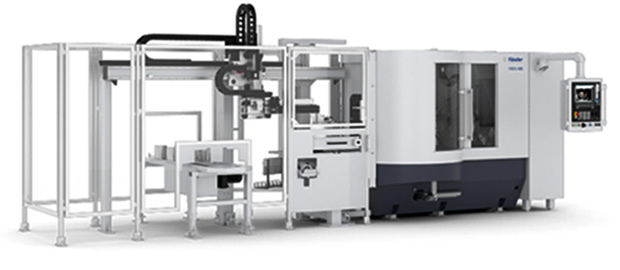

| Power Gear Honing Machine | Swiss | Fässler | HMX-400 | 2 |